My first Lithium Battery Project

For my electro mobility projects I need some Lithium batteries. Buying them from stock turned out to be difficult since the need to be adapted to the specific needs of the vehicle. I therefore decided to build the battery packs myself. The first project is a 12V, 50Ah LiFePo4 battery for Magayon II.

Sourcing the components

While I was in “exile” in Germany, I bought a total of 36 cells for three battery projects, one 12V and two 48V battery packs. This was a bit of an adventure because they are not available off the shelf in the Philippines and buying them online on Alibaba bears a big risk in terms of getting fakes, used cells or cells that don’t perform according to the specs. The internet is full of those stories. So after a lot of research in respective internet fora I ended up ordering cells from a guy who has a solar power company in Norway. They still came directly from China to the Philippines, but arranged for by somebody who regularly buys from that particular Chinese company, and thus must have some trust in the quality of the product they offer.

The DALI Battery Management System BMS I sources in the Internet and bought through AliExpress from a source that was recommended by another builder. Small components like busbars and materials for the housing I also bought through online shopping, mostly from Lazada but also from Amazon when I could not source it from Lazada.

Connectors I bought at CONRAD.

I bought a total of 36 cells for three battery projects, one 12V and two 48V battery packs. The batteries were tested by the company and supposedly matched by capacity by them. They had stickers on them which I assume are the test results. First step was to sort them in ascending sequence to make sure that each battery pack had similar capacity cells.

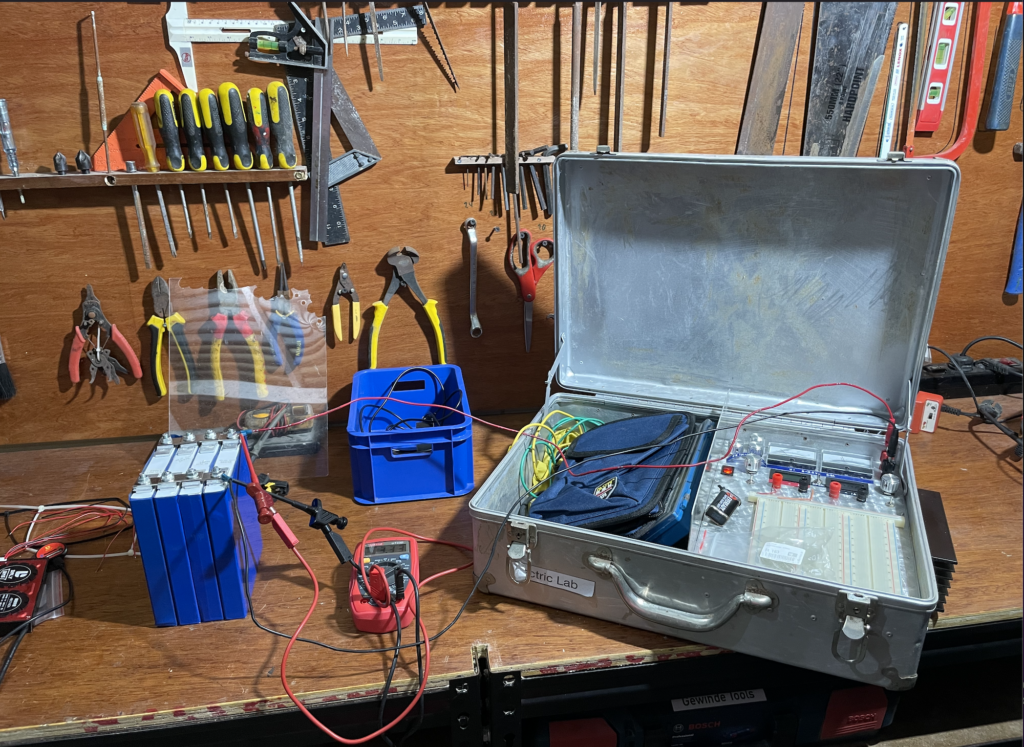

Top balancing the batteries

I used the four cells with the lowest capacity for the first 12V project and stored the remaining ones for later use. They had an average voltage of 3.1V with 3.0V as the lowest and 3.3 being the highest. To have optimum capacity of the battery pack, they need to be balanced, meaning all at the same rate of charge. One can either do top balancing by charging them to the end voltage of 3.65V or minimum balancing by charging them to the end of discharge voltage. I will do top-balanceing before connecting them in series and attaching the BMS. For top-balancing they are all connected parallel and then connected to my laboratory power supply (max. 3A) set to the end voltage of 3.65V. This will take a few days since the charge current is so low.

To be continued……