Some minor repairs before moving to Subic

January 2024

To do

After being moored in the Bangkal River for about a year and some vandalism by somebody who just wanted to have fun (nothing major stolen), we pulled Magayon II up to the Danacbunga beach just before Christmas 2023. Before moving her to a new home we need to do some minor repairs.

- Fix aft cross beam, port side. Water had penetrated through a whole in the fiberglass layer and softened to wood of the top beam over around 30 cm length

- Fix aft cross beam, starboard side. One plywood panel absorbed water after the fiberglass cover cracked under too much load of the swimming ladder

- Replace the broken locating blocks that hold the cockpit in place

- Replace the second Canvass Seat that now has a hole big enough for a foot to go through.

- Finish the internal fuel tank

- New bases for the winches

- Do some other minor repairs

- Replace broken / stolen components

After discussing several options for repairs including making a new aft cross beam I decided to repair it so that we can move the boat, possibly to Watercrafts in Subic. It would be very difficult on the sandy beach here to re-align the two hulls after one cross beam had been removed and replaced. That would be better done in a marina on leveled dry land, if it is still necessary after the repairs.

First thing is to purchase new materials and bring the woodworking and fiberglass materials and the tools from Los Baños. I am still dreaming of a VW bus with modular back that can be converted in either a camper van or a workshop vehicle, based on the mission of the travel.

Sourcing Quality Plywood and other Materials

Laminating epoxy was ordered from Los Banos on Shopee with shipment directly to Sundowners. It arrived on January 15. Plywood I planned to buy in Subic, but the only accredited Santa Clara marine plywood supplier north of Manila was closed on Sunday, so I would have to come back during the week. Other materials needed I hoped to get in local hardware stores. I did bring some hardwood beams from Los Banos, just in case I could not source any good wood in Zambales.

The location, not too bad to work on a boat

Magayon is currently beached at Danacbunga beach at Iba, Zambales, around 30 meters from Miriam’s and Regis little beach house. Since there were no events planned for some time I could find refuge in the Sundowners Villas event room, a 5 minute walk from the boat. So ideal conditions for the repairs.

During the first week Kata and Mavic were here too, so we had a few sundowners and meals at the Beach Club of Sundowners Villas.

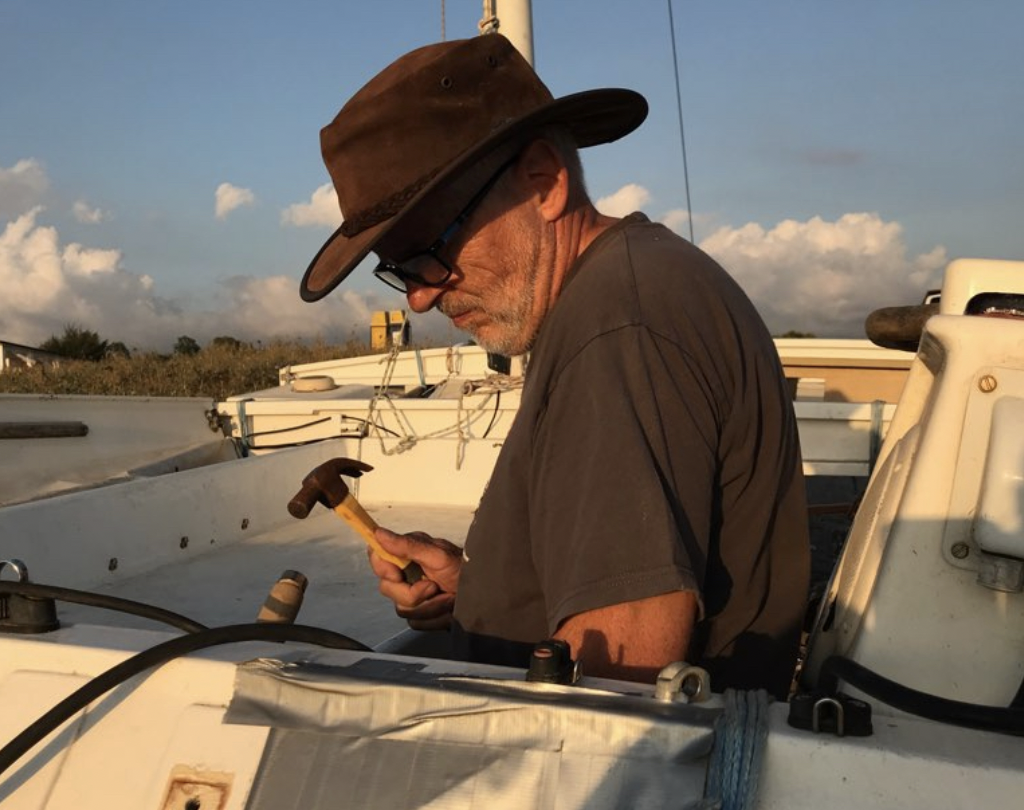

Day 1: Assessment and initial works

Zambales is terribly hot. So the plan is to work on the boat in the mornings and evenings and do a siesta and some computer based work during the day. Today I started with unmounting the winches and removing the old, rotten winch plates. I had done a pretty good job with solid wood and metal screws when mounting the winches and the plates, so it took some time to undo those. I filled the screw holes with marine epoxy, in the afternoon dark clouds appeared and I was worried it would rain.

Started on the aft cross beam. I do not want to remove too many lashings at the same time to make sure that the hulls do not move during the repair. It would be difficult to re-align them on the sandy beach. So I started with the port side, the starboard side would need to wait.

The port end of the aft cross beam had absorbed water and the wood of the upper layer beam was softened. So I opened it up and removed the spoilt wood. It will need a new beam, around 0.7m long. The hard wood pieces I brought are too narrow, so I will have to try to find a beam tomorrow, otherwise glue two smaller pieces together.

In the evening once it was not so hot anymore I cut parts from hard wood that I had brought from Los Baños for the new winch bases and the locating blocks for the cockpit. Since I had no matching big wooden piece for the locating blocks I assembled them from three layers of 15 mm thick beam and glued them together with epoxy.

Found out that another part was removed and stolen. A stainless steel eye at the aft of the port hull. Damn low-lifes. The gib halliard was also untied, luckily still in place be case to replace it we would need to lower the mast. When I came back to the boat in the afternoon a family had put bamboo beams across the hulls in the back and built a tent underneath. I was very upset but tried to keep my temper. Told them that they probably have a car and also don’t want strangers to sit on it and pointed out the scratched solar panels and that I might hold anybody who climbs on the boat accountable for all the damage. They apologized and removed all their stuff. But probably they see me as the evil rich guy as I see the billionaires. It is a pity that there is so much inequity in this world.

Day 2: Purchasing parts and supplies

Tuesday, January 9, 2024

Making progress in fixing Magayon ll. Removed broken parts yesterday. Went to Subic today to buy plywood and supplies. One useful feature of our pseudo SUV. You can transport full size plywood boards on its roof without a roof rack. Made 6 replacement parts the last two days and will start mounting them tomorrow. Ahead of schedule, also because the aft crossbeam can be fixed and does not have to be remade. Only annoying thing is all these kids climbing on the boat every day and doing further damage. Solar panels scratched and and more part stolen. Yesterday a family even used our boat to build a family tent on the beach.

Day 3: Starting the repairs

Wednesday, January 10, 2024

I had two official work meetings scheduled for today. So boat work needed to be scheduled around those. In the morning I cleaned up the aft cross beam by removing all rotten wood and power sanding the surfaces plane, then fitted the new beam to the aft crossbeam top using the Japanese saw for making the scarf joint, and made the fillets for the cleat holes from marine epoxy.

After the official meetings in the later afternoon I glued on the top layer, secured it with stainless steel screws and covered everything with duct tape in case it rains overnight. I also sanded the winch bases that I had covered with fiberglass yesterday and drilled holes for mounting them. Before heading off for dinner I glassed the new cockpit locating blocks that I had assembled yesterday. Glassing of the top aft crossbeam, mounting the winch bases, making port rudder height adjustments and designing the wooden port seat and the starboard aft crossbeam fairing will be on the agenda.

Day 4: Continued repairs

Sanded the cabin tops where the winches were located. Mounted the winch bases with lots of epoxy and fixed with screws. Filled the screw holes with marine epoxy and made fillets around the bases.

Morning: glassed the repaired aft cross beam, port side and used the remaining epoxy resin to coat the winch plates again.

Measured and cut the plywood for the port seat to size.

Second glassing of the locating blocks after sanding the first layer. Selected screws, and washers and nuts for the starboard block and drilled the wholes.

Took the starboard seat out with the help of Miriam and Mavic. Placed it on the trampoline.

Lunch at chubby Yam Yams

Evening: I went back at 17:00, so I only had one hour. Sanded the locating block leftovers on starboard and then mounted the new block with lots of marine epoxy. Fastened it with the screws. It got dark quickly.

Dinner at Miriams, Salad and Pumkin soup.

Day 5:

Went on a hike this morning to the waterfall. Miriam, Regis, Kata, Mavic and the dogs. So no work on the boat in the morning.

Slept after brunch (tuna steak in the resto) until around 4:00

Work on the boat:

Collected the stainless steel screws, washers and nuts and drilled the holes in the port locating block. Removed old epoxy and mounted the block with lots of marine epoxy, fastening it with the screws. Filled the screw holes in nothing blocks and made fillets to ensure everything is 100% watertight. Then the darkness set in.

Day 6: Saturday

Morning: Sanded the locating blocks, aft crossbeam port end, and the winch bases again.

Removed the rotten wood of the aft cross beam, starboard side, turned out that it is still very much intact so I only need to fix a small part of the fairing panel and add a thicker layer as reinforcement for the swimming ladder.

Made two fitting slats and coated them with epoxy.

Day 7: Sunday

Morning: Glued the fitting slats to the fairing and fixed them with wood screws. Made the replacement panel for the fairing and matched it with the opening. Coated the back with laminating epoxy. Made reinforcements of 15mm hardwood board for the swimming ladder, fitted them into the attachment, glued them to to the replacement panel.

Went to Botolan to buy some stainless steel wood screws, have a cold drink and some chicken nuggets for lunch.

Afternoon: Measured the swimming ladder fitting, transferred it to the replacement panel and made 4 large marine epoxy fillets for the screws that hold the swimming ladder. Coated the reinforcement beams with epoxy.

Cleaned the tank opening area of the starboard seat off the duct tape. Found out that the screws are too small, have to go to Botolan again, maybe Wednesday.

Dinner: Toast and fried veggies at Miriam’s restaurant. FaceTime call with the Amihan CataNaya group for planning their trip to the Philippines, Los Banos, Zambales, Botolan, Bulinao, Chico River, Batad and Sagada, Sailing cruise on Naya ending on Pandan Island.

Day 8: Monday

Morning: Mounted the replacement panels with lots of screws and marine epoxy into the aft cross beam. Before that made sure that there is no untreated wood inside. Filled the smaller hole for the outboard motor rope with epoxy and a small plywood panel.

Had to do some work for earning a living during the day.

Day 9: Tuesday, January 16

I had to do some work for my consulting projects today, so the boat work consisted basically only of one task: Glassing the aft crossbeam.

I got up at 6:30 but until I had freshened up, a cup of tea and done some urgent emails it was around 8:00 until I could start working on the boat. The first step was sanding the replacement panel and the cross beam surfaces surrounding it as preparation for the glassing. I decided on three layers of fiberglass for additional support of the swimming ladder, the original only had one layer of rowing mat. I hate sanding, it is my most unliked job. It took around 30 minutes to get a good enough surface. I have high respect for the Du Pond boat paint we used, it is very hard and takes ages to remove, a lot more difficult than the epoxy primer underneath or the marine epoxy I had used yesterday, although that is not fully cured yet. I then applied a large fiberglass mat with lots of overlap in the morning, the job was done at 11:00. A second, smaller fiberglass patch followed at 14:00 and another one just before sunset at 17:30. This came with the feeling of a major achievement since the main repairs are now done. The rest is basically one more sanding, priming and then top coating.

Miriam went to Iba to buy 12 stainless steel screws for the fuel tank integrated in the starboard seat. The original screws were too short. I booked my ticket to Thailand and fine tuned the planning for the next 6 weeks.

Saturday, January 20

Last day of Magayon 2 repairs. The aft crossbeam, one of the most important structural parts since it keeps the hulls in place, holds the cockpit and supports the motor is fully restored, and structurally strengthened do withstand weight on the swimming ladder.

I must admit, I had some frustrations. People always climbing up to have their photo taken, drink beer or smoke weed. I even found a used condom in the cockpit one morning. When I approach them and ask them whether they have a car or a motorbike, and whether they would like it if I just sit on those, they usually walk away without a word. This morning I caught an American, who had lifted his Pinay partner onto the starboard hull to take a picture, exactly where I had applied epoxy topcoat yesterday. Now I have a woman‘s bottom imprint on the deck (picture). At least she had the decency to apologize.

The weed smokers are the ones I can tolerate. They ask for permission and also sometimes offer a joint. There is one family with a handicapped elderly who came several times and sat next to the boat in the shade. They do nice „good morning“s. They are OK. Another annoyance is the trash that almost everybody leaves behind (picture).

Interesting two weeks with lots of work in the Zambales heat, beers and meals in the Sundowners Villas Beach club and quite a lot of socializing.

Appendix

Sources of Santa Clara Marine Plywood:

NORTWEST CONST. SUPPLY

#209 National Highway, Brgy. Ilwas, Subic, Zambales

(047) 232-3500

LAGUNA:

EVERPLY TRADING CORPORATION | (049) 502-1121

GOLDEN LION CONSTRUCTION SUPPLY CORP. | (049) 544-7833

NEW SAN PABLO TRADING | (049) 562-0168

Authorized Dealers for NCR Area:

MEGA ORO TRADING

112 Katipunan Street, Balintawak, Caloocan City, Metro Manila

(02) 8361-8576; 8361-8578; 8361-1694

NATUREWOOD MARKETING CORPORATION

#22 MGM Industrial Compound Sitio Gitna, Kaybiga, Kalookan City

(02) 8938-6756; 8938-7131; 0999-881-7042; 0932-850-7800

TOPAN MARKETING CORPORATION

132 Sgt. E. Rivera St., Manresa, Quezon City

(02) 8366-3663; 8366-3773; 8366-3883; (02) 8366-7890; 8330-3888 | topanmarketing@gmail.com

UPWARD SALES ENTERPRISE

No. 11 ROTC Hunter Street, Tatalon, Quezon Cit

(02) 8711-2717; 8712-2856; (02) 8743-8474; 8732-0675

WILCON DEPOT, INC.

#90 E.Rodriguez Jr. Ave., Ugong Norte, Libis, Quezon City

(02) 8634-8387